Lenane la Kereiti

Zhuzhou Jintai Cemented e etsa mefuta e 2000 e fapaneng ea malebela a tloaelehileng a lumellanang le ISO (International Standard), BSS (British Standard), SMS (Swedish Standard) le DIN (Maemo a Jeremane).Zhuzhou Jintai Cemented e ntlafalitse Mephato ea eona ea Sintered Metal Cutting e tsamaellanang le maemo a ISO.

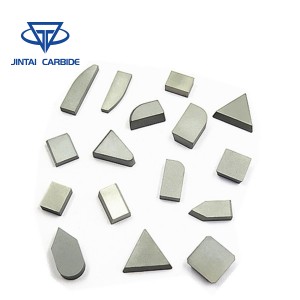

Ntle le malebela a tloaelehileng, Zhuzhou Jintai Cemented e tsoela pele ho leka ho hlahisa malebela a khethehileng a hahiloeng ka tloaelo bakeng sa liindasteri tse fapaneng tse kang Automobile, Engineering, Shoe Accessories, Textile, Tsoekere, joalo-joalo. Tse ling tsa lihlahisoa tse hlahelletseng tse ntlafalitsoeng ka katleho ke Blanks for Rotary Burrs, Malebela a mofuta. lisebelisoa, lifolete tsa lithipa, lithulusi tsa Scarfer, malebela a lisebelisoa tsa grooving, lithupa tsa lisebelisoa tse tenang, likheo tse sehang, joalo-joalo.

Likaroloana

1. 100% lisebelisoa tse tala tsa WC + CO

2. Theko ea Wholesale le boleng bo phahameng bo tsitsitseng

3. Tekanyetso ea ISO

4. OEM & ODM Service.

5. Kopo: Ho fetola, ho sila, ho kopanya le ho arohana joalo-joalo Bakeng sa ho qeta, ho qeta, ho qeta, ho senya le ho senya tšepe, tšepe ea tšepe, tšepe ea alloy, tšepe ea tšepe, tšepe e sa hloekang joalo-joalo.

6. Tšobotsi e ikhethang: boleng bo botle ba ho itšeha, bohanyetsi bo phahameng le tšebeliso e telele ea bophelo bohle.

7. Mofuta o hlophisitsoeng: re ka hlahisa lehare la carbide e le setšoantšo sa moreki, boholo le tlhokahalo.

Lenane la Kereiti

| Kereiti | Khoutu ea ISO | Thepa ea 'Mechanical (≥) | Kopo | ||

| Botenya g/cm3 | Ho thatafala(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | E loketse bakeng sa machining e nepahetseng ea tšepe e entsoeng ka tšepe le litšepe tse se nang ferrous. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | E loketse bakeng sa ho sebetsa ka mokhoa o nepahetseng le ho qeta litšepe tse entsoeng ka tšepe le tse se nang ferrous, hammoho le ho sebetsana le tšepe ea manganese le tšepe e tingoeng. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | E loketse bakeng sa ho qeta le ho etsa machining a tšepe a tšepe le lisebelisoa tse bobebe, hape e ka sebelisoa bakeng sa machining a mabe a tšepe ea tšepe le tšepe e tlase ea alloy. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | E loketse ho cheka mafika a rotary le likotoana tsa ho cheka mafika. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | E loketse ho kenya likotoana tsa meno tse nang le sebopeho sa chisel kapa tse kholo bakeng sa mechini e boima ea ho cheka mafika ho sebetsana le mafika a thata. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | E loketse tlhahlobo e tsitsitseng ea litšepe le liphaephe tsa tšepe tlas'a litekanyetso tse phahameng tsa khatello. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | E loketse ho etsa stamping die. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | E loketse ho etsa litempe tse batang le ho hatella ho batang bakeng sa liindasteri tse kang likarolo tse tloaelehileng, li-bearings, lisebelisoa, joalo-joalo. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | E loketse bakeng sa machining e nepahetseng le ho qeta halofo ea tšepe e sa hloekang le tšepe e akaretsang ea alloy. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | E loketse ho qeta halofo ea tšepe e sa hloekang le tšepe e tlase ea alloy. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | E loketse bakeng sa ho sebetsa ka mokhoa o nepahetseng oa li-alloys tse thehiloeng ho tšepe tse thehiloeng ho nickel le litšepe tse matla haholo. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | E loketse ho itšeha ka thata-thata ea tšepe le tšepe ea tšepe. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | E loketse bakeng sa machining e nepahetseng le ho qeta halofo ea tšepe le tšepe ea tšepe. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | E loketse bakeng sa ho sebetsa ka mokhoa o nepahetseng le ho qeta litšepe le tšepe e entsoeng ka tšepe, ka tekanyo ea phepo e itekanetseng.YS25 e etselitsoe ka ho khetheha ts'ebetso ea ho sila ka tšepe le tšepe. |

| YC45 | P40/P50 | 12.5-12,9 | ≥90 | ≥2000 | E loketse lisebelisoa tsa ho itšeha tse boima, e fanang ka litholoana tse ntle haholo mabapi le ho phethoha ho hoholo ha li-castings le litšepe tse fapaneng. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | E loketse ho kenya likotoana tsa ho cheka mafika a rotary le ho cheka ka mafika a thata le a batlang a le thata. |

Mokhoa oa ho laela

Mokhoa oa Tlhahiso

Sephutheloana