Tlhaloso

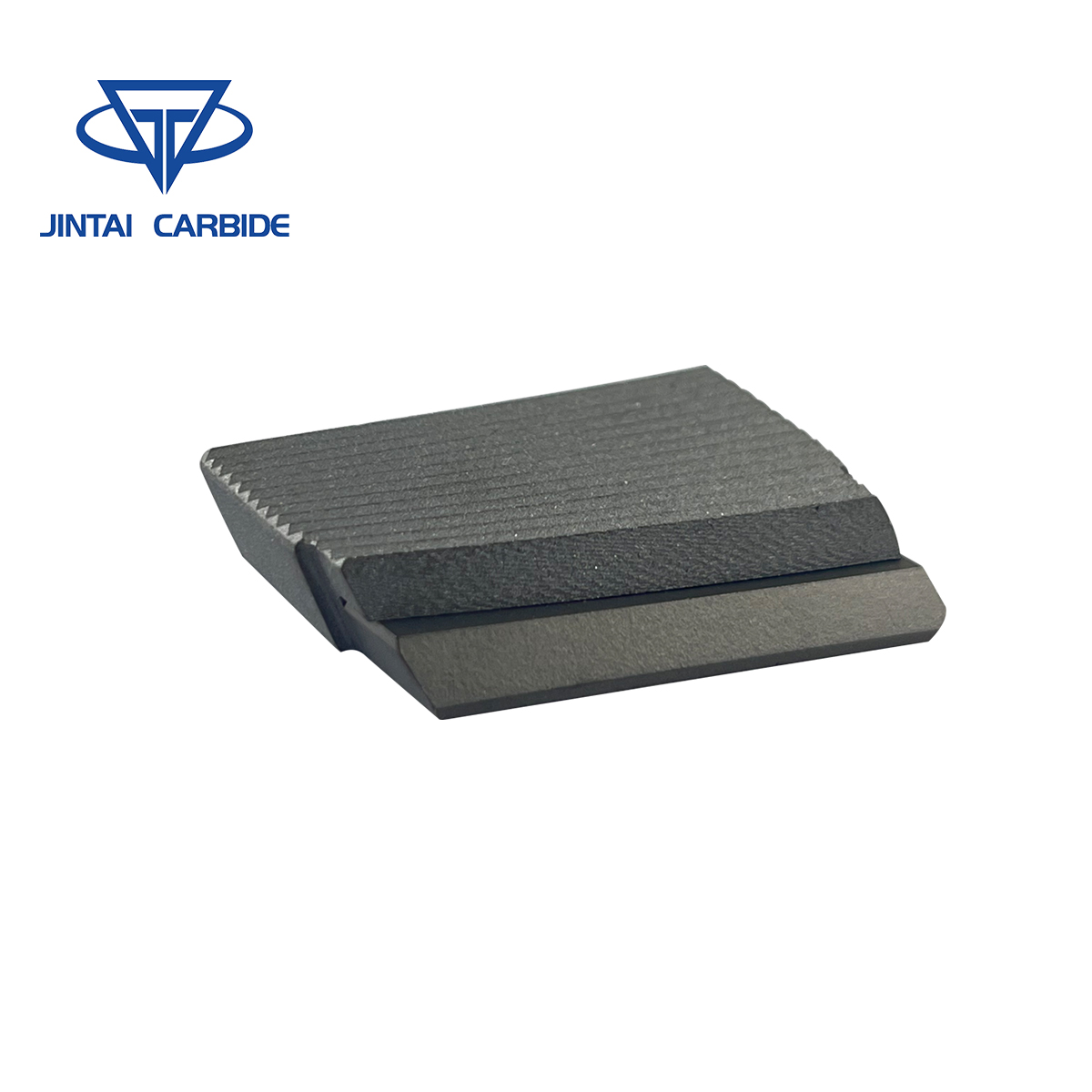

Li-blades tsa Carbide hangata li sebelisoa lisakhang tse kang lisakha tse chitja tsa letsoho, lisakha tsa miter le lisaha tsa tafole tse tsitsitseng.Likotoana tse nyane tsa tšepe ea carbide li sirelelitsoe ka lehare la tšepe le chitja.Epoxy e thibelang mocheso o phahameng e sebelisoa ho tšoara meno a carbide sebakeng.Meno a Carbide a na le molemo oa ho ba thata haholo, kahoo a ka boloka bohale bo bohale ka nako e telele haholo

1. Mephato: YG6X,YG6,YG8,YG8X,JX10,JX15,JX35,JX40 joalo-joalo.

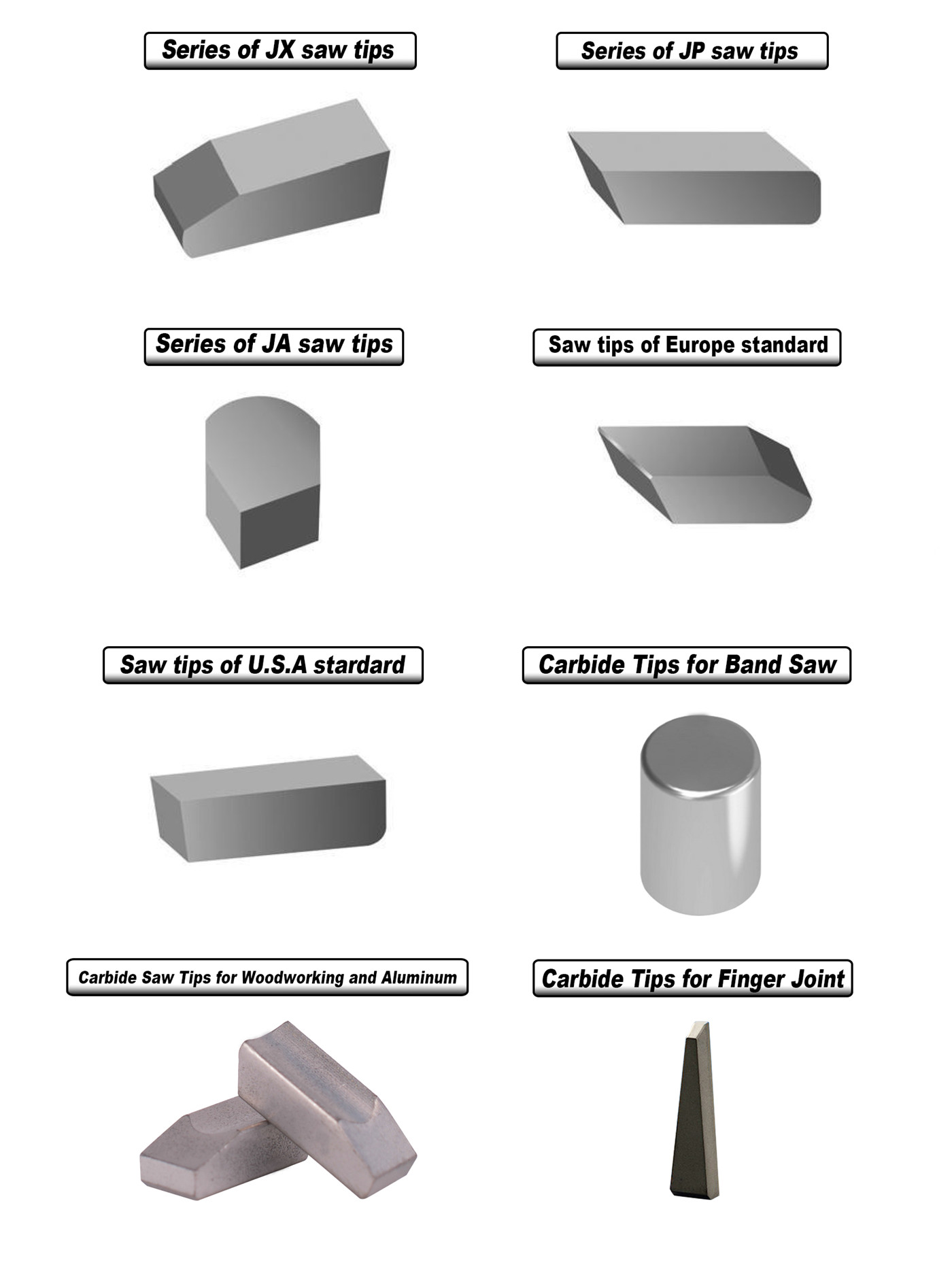

2. malebela a sakha a kenyelletsa letoto la JX, letoto la JP, letoto la JA, USA Standard le European Standard joalo-joalo.

3. Litlhahiso tsohle tsa saw ke HIP-Sintered, ho netefatsa boleng ba boleng bo phahameng, ka ho tobetsa ka mokhoa o itekanetseng ho etsa bonnete ba hore boholo bo nepahetseng, tumble le nickel li koahetsoe ho etsa bonnete ba hore ts'ebetso e ntle ea brazing.

4. Letšoao la rona le na le botumo bo botle ho tsoa ho bareki ba Europe, USA, Asia, joalo-joalo.

5. Limaraka tsa rona li akaretsa mefuta eohle ea ISO, e loketseng ho poma joang, lehong le thata, lehong le sebelisoang hape, tšepe, polasetiki, PVC, MDF, boto ea Melamine, plywood, joalo-joalo.

Matla a phahameng le khanyetso ea ho robeha, li-blades tsa rona tsa saw li etselitsoe ho tsitsisa le ho tšepahala.Ho sa tsotelehe hore na u seha lisebelisoa life, li-blades tsa rona li tla lula li fana ka ts'ebetso e ntle.Ebang ke lehong, tšepe, kapa polasetiki, li-sakha tsa rona li thella ka thata ho u fa likheo tse phethahetseng nako le nako.

Lisebelisoa tsena li na le boima bo phahameng, ho hanyetsa ha fracture le ts'ebetso ea sintering ea HIP e tiisang botsitso, ho tšepahala le ho itšeha nako e telele.Tlhahiso ea rona ea morao-rao e ikemetseng e tiisa boleng bo tsitsitseng le katleho e kholoanyane, ha ts'ehetso ea rona bakeng sa mefuta e mengata ea litlhaloso le mekhoa ea ho iketsetsa khetho e finyella litlhoko tsohle tsa hau tse fapaneng tsa ho itšeha.

Notlolla bokhoni ba morao-rao ba Malebela a Tungsten Carbide Saw!Joaloka motho ea chesehelang khoebo ea e-commerce, u fihlile sebakeng se nepahetseng bakeng sa malebela a pele a Tungsten Carbide Saw a ipabolang lits'ebetsong tse fapaneng tsa ho itšeha, a netefatsa ts'ebetso e holimo le nako e telele ea bophelo.

E entsoe ka boitseanape ka mokhoa o nepahetseng, Malebela a rona a Tungsten Carbide Saw a ithorisa ka ho thatafala ho ikhethang le ho se mamelle, e leng se etsang hore e be khetho ea ho qetela bakeng sa mesebetsi ea ho lisakha mesebetsing ea mapolanka, ho sebetsa ka tšepe le tse ling.Tšepa malebela ana ho fana ka litšitiso tse nepahetseng le ho tšoarella ho ke keng ha lekanngoa, ho fetola mekhoa ea hau ea ho itšeha.

Eseng feela e thata, Malebela a rona a Tungsten Carbide Saw a bonts'a khanyetso e ikhethang ea mocheso, e netefatsa ts'ebetso e tsitsitseng esita le maemong a mocheso o phahameng.Fumana bokhoni ba bona ba ho boloka bohale le ho ts'epahala, ho u thusa ho ntlafatsa tlhahiso le ho fokotsa nako ea ho theoha.

Ho JINTAI, re motlotlo haholo ka ho fana ka lihlahisoa tse fihlelang litekanyetso tsa boleng bo holimo.Keletso e 'ngoe le e' ngoe ea Tungsten Carbide Saw e etsa tlhahlobo e matla, e netefatsang botsitso le bokhabane, e u fa matla a ho fihlela litholoana tse ntle mererong ea hau ea ho itšeha.

Amohela ts'ebetso e ntle le ho baballa litšenyehelo ka malebela a rona a pele a Tungsten Carbide Saw, 'me u fumane maemo a tlholisano indastering ea hau.Selekane le rona kajeno ho bona ts'ebetso e ke keng ea bapisoa le malebela ana a tlisa ts'ebetso ea hau ea ho itšeha.

Khetha JINTAI bakeng sa malebela a boleng bo holimo a Tungsten Carbide Saw, 'me u bone bokhoni ba bona ba 'nete ba ho phahamisetsa khoebo ea hau holimo.Beha odara ea hau hona joale 'me u sebelise matla a litharollo tsa rona tsa maemo a holimo.

Lenane la Kereiti

| Kereiti | Khoutu ea ISO | Thepa ea 'Mechanical (≥) | Kopo | ||

| Botenya g/cm3 | Ho thatafala(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | E loketse bakeng sa machining e nepahetseng ea tšepe e entsoeng ka tšepe le litšepe tse se nang ferrous. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | E loketse bakeng sa ho sebetsa ka mokhoa o nepahetseng le ho qeta litšepe tse entsoeng ka tšepe le tse se nang ferrous, hammoho le ho sebetsana le tšepe ea manganese le tšepe e tingoeng. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | E loketse bakeng sa ho qeta le ho etsa machining a tšepe a tšepe le lisebelisoa tse bobebe, hape e ka sebelisoa bakeng sa machining a mabe a tšepe ea tšepe le tšepe e tlase ea alloy. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | E loketse ho cheka mafika a rotary le likotoana tsa ho cheka mafika. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | E loketse ho kenya likotoana tsa meno tse nang le sebopeho sa chisel kapa tse kholo bakeng sa mechini e boima ea ho cheka mafika ho sebetsana le mafika a thata. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | E loketse tlhahlobo e tsitsitseng ea litšepe le liphaephe tsa tšepe tlas'a litekanyetso tse phahameng tsa khatello. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | E loketse ho etsa stamping die. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | E loketse ho etsa litempe tse batang le ho hatella ho batang bakeng sa liindasteri tse kang likarolo tse tloaelehileng, li-bearings, lisebelisoa, joalo-joalo. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | E loketse bakeng sa machining e nepahetseng le ho qeta halofo ea tšepe e sa hloekang le tšepe e akaretsang ea alloy. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | E loketse ho qeta halofo ea tšepe e sa hloekang le tšepe e tlase ea alloy. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | E loketse bakeng sa ho sebetsa ka mokhoa o nepahetseng oa li-alloys tse thehiloeng ho tšepe tse thehiloeng ho nickel le litšepe tse matla haholo. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | E loketse ho itšeha ka thata-thata ea tšepe le tšepe ea tšepe. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | E loketse bakeng sa machining e nepahetseng le ho qeta halofo ea tšepe le tšepe ea tšepe. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | E loketse bakeng sa ho sebetsa ka mokhoa o nepahetseng le ho qeta litšepe le tšepe e entsoeng ka tšepe, ka tekanyo ea phepo e itekanetseng.YS25 e etselitsoe ka ho khetheha ts'ebetso ea ho sila ka tšepe le tšepe. |

| YC45 | P40/P50 | 12.5-12,9 | ≥90 | ≥2000 | E loketse lisebelisoa tsa ho itšeha tse boima, e fanang ka litholoana tse ntle haholo mabapi le ho phethoha ho hoholo ha li-castings le litšepe tse fapaneng. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | E loketse ho kenya likotoana tsa ho cheka mafika a rotary le ho cheka ka mafika a thata le a batlang a le thata. |

Mokhoa oa ho laela

Mokhoa oa Tlhahiso

Sephutheloana

-

Tungsten Carbide Oa Shoa - Ho Tepella Hoa Shoa 'me ...

-

Keletso ea ho sebetsa ka lehong ea Tungsten Carbide & STB

-

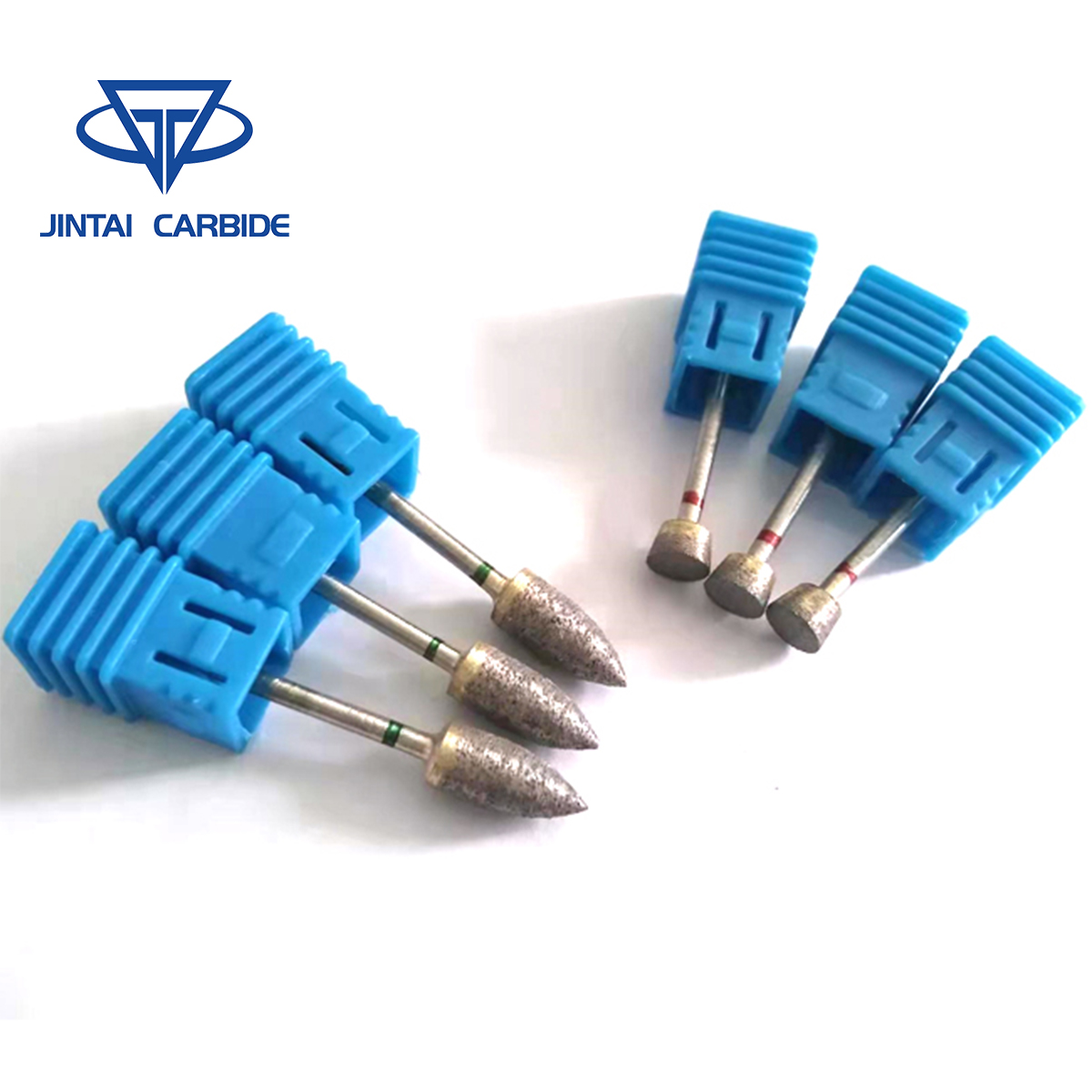

Tungsten Carbide Rotary Burr Kapa Die Grinder Bits

-

Tungsten Carbide Fiber Optic Cleaver Replacemen...

-

Tungsten Carbide ISO Standard Brazed Tips

-

Tungsten Carbide Scalping Cutter Bakeng sa Koporo Le...