Tlhaloso

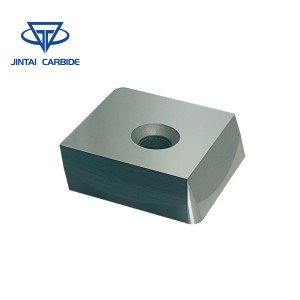

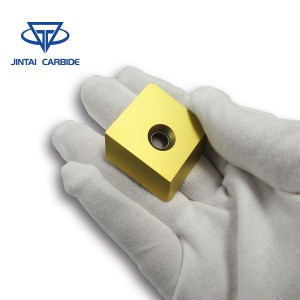

Sehahi sa Milling Sefahleho Bakeng sa Ingot ea Aluminium

Kakaretso ea Sehlahisoa:

Aluminium ingot face milling cutter e etselitsoe ho siloa ka holim'a metsi pele ho chesa

tshebetso ya aluminium ingots.The aluminium lintho tse bonahalang sefahleho sila sehang letoto la lihlooho tse akarelletsa kaba

li-milling cutters, li-cutter tse nepahetseng tsa ho sila, le li-cutter tse koloiloeng

e sebelisoa bakeng sa ho sila ka bongata ba likheo tse mahoashe.Seha se nepahetseng sa ho sila se sebelisetsoa ho ntlafatsa

bokaholimo bo boreleli ba li-ingots tsa aluminium.Seha se koaetsoeng sa ho sila se ntlafatsa ho hanyetsa le nako ea bophelo ea mahare.

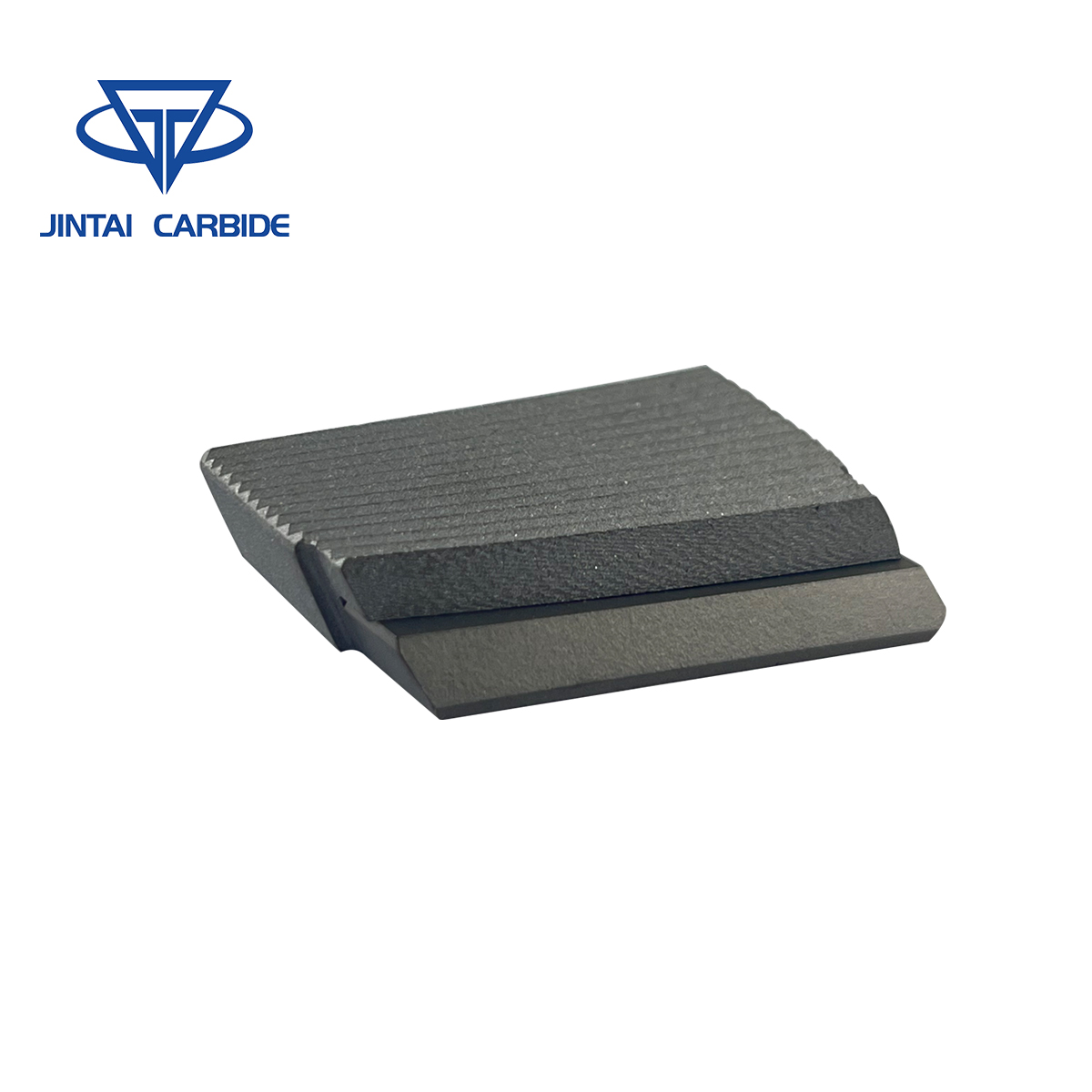

Likarolo tsa Sehlahisoa:

1, Moeli oa ho sila o bohale, o fella ka sebaka se boreleli holim'a ingot e entsoeng ka aluminium, e ntle.

botsitso ba ho sebetsa.

2, Lehare le na le sekhahla se phahameng le botsitso, le fana ka khanyetso e ntle haholo le ho hanyetsa ho roala.3, Sebaka sa lehare se na le boreleli bo botle, ho netefatsa ts'ebetso e sa tsitsang le e sa cheseng.

Rough Milling Cutter:

| Khoutu ea Odara | Boholo(mm | ||||

| L | R | d | S | s1 | |

| JT6206-L | 37.4 | 3 | 7 | 8 | 2 |

| Khoutu ea Odara | Boholo(mm) | ||||||

| L | R | S | S1 | S2 | d | d1 | |

| JT6206-M | 30 | 3 | 8 | 2.4 | 0.65 | 8.2 | 7.2 |

Qetella Milling Cutter:

| Khoutu ea Odara | Boholo(mm) | ||||||

| L | L1 | R | R1 | S | S1 | d | |

| JT6027 | 37.4 | 37.08 | 3 | 730 | 8 | 2 | 7.4 |

Coated Milling Cutter:

Lenane la Kereiti

| Kereiti | Khoutu ea ISO | Thepa ea 'Mechanical (≥) | Kopo | ||

| Botenya g/cm3 | Ho thatafala(HRA) | TRS N/mm2 | |||

| YG3X | K05 | 15.0-15.4 | ≥91.5 | ≥1180 | E loketse bakeng sa machining e nepahetseng ea tšepe e entsoeng ka tšepe le litšepe tse se nang ferrous. |

| YG3 | K05 | 15.0-15.4 | ≥90.5 | ≥1180 | |

| YG6X | K10 | 14.8-15.1 | ≥91 | ≥1420 | E loketse bakeng sa ho sebetsa ka mokhoa o nepahetseng le ho qeta litšepe tse entsoeng ka tšepe le tse se nang ferrous, hammoho le ho sebetsana le tšepe ea manganese le tšepe e tingoeng. |

| YG6A | K10 | 14.7-15.1 | ≥91.5 | ≥1370 | |

| YG6 | K20 | 14.7-15.1 | ≥89.5 | ≥1520 | E loketse bakeng sa ho qeta le ho etsa machining a tšepe a tšepe le lisebelisoa tse bobebe, hape e ka sebelisoa bakeng sa machining a mabe a tšepe ea tšepe le tšepe e tlase ea alloy. |

| YG8N | K20 | 14.5-14.9 | ≥89.5 | ≥1500 | |

| YG8 | K20 | 14.6-14.9 | ≥89 | ≥1670 | |

| YG8C | K30 | 14.5-14.9 | ≥88 | ≥1710 | E loketse ho cheka mafika a rotary le likotoana tsa ho cheka mafika. |

| YG11C | K40 | 14.0-14.4 | ≥86.5 | ≥2060 | E loketse ho kenya likotoana tsa meno tse nang le sebopeho sa chisel kapa tse kholo bakeng sa mechini e boima ea ho cheka mafika ho sebetsana le mafika a thata. |

| YG15 | K30 | 13.9-14.2 | ≥86.5 | ≥2020 | E loketse tlhahlobo e tsitsitseng ea litšepe le liphaephe tsa tšepe tlas'a litekanyetso tse phahameng tsa khatello. |

| YG20 | K30 | 13.4-13.8 | ≥85 | ≥2450 | E loketse ho etsa stamping die. |

| YG20C | K40 | 13.4-13.8 | ≥82 | ≥2260 | E loketse ho etsa litempe tse batang le ho hatella ho batang bakeng sa liindasteri tse kang likarolo tse tloaelehileng, li-bearings, lisebelisoa, joalo-joalo. |

| YW1 | M10 | 12.7-13.5 | ≥91.5 | ≥1180 | E loketse bakeng sa machining e nepahetseng le ho qeta halofo ea tšepe e sa hloekang le tšepe e akaretsang ea alloy. |

| YW2 | M20 | 12.5-13.2 | ≥90.5 | ≥1350 | E loketse ho qeta halofo ea tšepe e sa hloekang le tšepe e tlase ea alloy. |

| YS8 | M05 | 13.9-14.2 | ≥92.5 | ≥1620 | E loketse bakeng sa ho sebetsa ka mokhoa o nepahetseng oa li-alloys tse thehiloeng ho tšepe tse thehiloeng ho nickel le litšepe tse matla haholo. |

| YT5 | P30 | 12.5-13.2 | ≥89.5 | ≥1430 | E loketse ho itšeha ka thata-thata ea tšepe le tšepe ea tšepe. |

| YT15 | P10 | 11.1-11.6 | ≥91 | ≥1180 | E loketse bakeng sa machining e nepahetseng le ho qeta halofo ea tšepe le tšepe ea tšepe. |

| YT14 | P20 | 11.2-11.8 | ≥90.5 | ≥1270 | E loketse bakeng sa ho sebetsa ka mokhoa o nepahetseng le ho qeta litšepe le tšepe e entsoeng ka tšepe, ka tekanyo ea phepo e itekanetseng.YS25 e etselitsoe ka ho khetheha ts'ebetso ea ho sila ka tšepe le tšepe. |

| YC45 | P40/P50 | 12.5-12,9 | ≥90 | ≥2000 | E loketse lisebelisoa tsa ho itšeha tse boima, e fanang ka litholoana tse ntle haholo mabapi le ho phethoha ho hoholo ha li-castings le litšepe tse fapaneng. |

| YK20 | K20 | 14.3-14.6 | ≥86 | ≥2250 | E loketse ho kenya likotoana tsa ho cheka mafika a rotary le ho cheka ka mafika a thata le a batlang a le thata. |

Mokhoa oa ho laela

Mokhoa oa Tlhahiso

Sephutheloana

-

Tungsten Carbide Fiber Optic Cleaver Replacemen...

-

Tungsten Carbide Scalping Cutter Bakeng sa Koporo Le...

-

Tungsten Carbide Plate - Cu e bentšitsoeng hantle ...

-

Tungsten Carbide Rod & Blanks OEM ODM Ava...

-

Tungsten Carbide ISO Standard Brazed Tips

-

Keletso ea ho sebetsa ka lehong ea Tungsten Carbide & STB